Innovative Heating for Tanks and Vessels

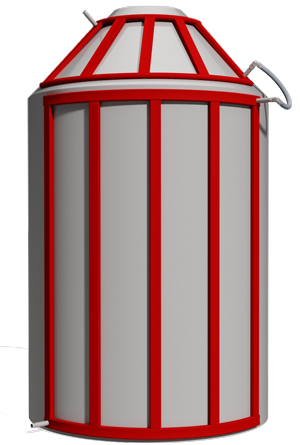

Storage tanks and vessels up to 25 feet in diameter are in service with ControTrace elements providing uniform heat over their entire surfaces. The ControTrace Element configuration can be designed for liquid or vapor heating media. A key benefit of ControTrace is that elements can be dispersed evenly around the vessel, assuring the uniform heat coverage. Jackets can be fabricated for conic heads as well as elliptical heads. Generally, systems that utilize a liquid heating medium are designed in a serpentine configuration. Systems that use a vapor heating medium are usually constructed for parallel medium flow. When parallel flow must be used on a liquid system, flow diverters can be placed inside the ControTrace assemblies to channel the liquid.

Features

- Robust construction, 2-3x thicker than typical tracing (SA‑178 Grade A boiler tube pressure rated per ASME Section VIII, Div.1)

- External heating systems allow easy maintenance & eliminate potential product contamination

- Conductive heat transfer path from the heating medium through the wall into the process with the aid of Heat Transfer Compound (HTC)

- Contoured to fit the tank/vessel diameter

- Panel configuration on tank/vessel

|

|

Heating Advantages

- Engineered for predictable heating performance and backed with the CSI thermal guarantee

- Robust construction (material 2x thicker than typical panel coil)

- Stainless Steel is available for aggressive environments

- Pressure rated in accordance with the ASME Boiler and Pressure Vessel Code, Section VIII, Div.1

- Even heat distribution

- Easy installation/field modification

- No cross-contamination concerns

- Low maintenance costs – external accessibility

- Global field support resources for install support

|

ControTrace on Tanks

In some applications (i.e. molten sulfur) tank corrosion can occur since an internal steam coil is not able to maintain the tank internal shell and roof above the freezing point of the process. Solids which form on the tank wall setup an environment for tank corrosion (SEE FIG XYZ). With ControTrace, the uniformly distributed external heating system maintains both the process temperature and the shell / roof wall temperature above the freezing point, preventing corrosion and allowing for easy access to the heating system for maintenance. ControTrace is easily customized and adapted to non-uniformities such as vents, nozzles or others XYZ (see pics XYX,1, XYZ2); whereas this type of detail is not possible with other heating systems (internal coils or dimple plates).

ControTrace on Vessels

The same principle applies with vessels. External ControTrace heating prevents processes from freezing on the internal vessel walls. Additionally, ControTrace can be design/fabricated to conform to any vessel geometry such as bottom cones, vessel heads, and around nozzles. Bolt-on ControHeat jackets can also be supplied to effectively heat nozzles. CSI takes responsibility for all project details-using clients drawings, CSI designs & delivers panels ready to bolt on to client’s equipment.

Advantages

- Provides a custom-fit, evenly distributed and thermally optimized coverage of tank, vents and nozzles.

- Field modifications to system is possible (no code stamp welding required).

- Supporting infrastructure optimized to reduce operating costs.

|

|

|

Problems with Internal Coils

- Uneven distribution of heating and accumulation of process on internal tank surfaces

- Accessibility issues for maintenance

- Risk of cross-contamination with process

- Coil corrosion which requires expensive and time-consuming repair

|

|

Problems with Panel Coils

- Not customizable to accommodate nozzle/tank protrusions or heating of nozzles

- Panel design utilizes long seam welds of thin material susceptible to corrosion and failure

- Gaps between panels leave large swaths of unheated tank surface

- Large distances between panels reduce opportunities for heating fluid circuit optimization

- Can’t maintain uniform vessel wall temperature

|