ControTrace® bolt-on heating elements have been the preferred steam tracing solutions for heating industrial process piping, tanks, and vessels since 1980. These thermal heating solutions are a cost-effective alternative to fully jacketed piping and, in comparison to traditional tube tracing, provide higher heating capacities and reliability. ControTrace heating elements eliminate the possibility of cross-contamination between the heating medium and the process that can occur in fully jacketed pipe solutions. Today, over five hundred miles of ControTrace® heat tracing elements are successfully installed and provide reliable performance in plants and refineries around the globe.

Why CSI ControTrace?

CSI’s Thermal Performance Guarantee

ControTrace’s engineered solution is guaranteed to meet your thermal performance objectives. This is accomplished with our heat transfer expertise, quality product and our long-time use of proprietary, finite thermal analysis and computational fluid dynamic computer modeling, utilizing years of project-based empirical modeling and feedback. The computer model has been corroborated time and again with empirical field data.

|

Fig 1: Example of thermodynamic modeling of heat transfer for a critical temperature maintenance application of a gas stream.1 |

|

Consideration for Thermodynamic Modeling

- Pipe size, wall thickness and properties

- Process fluid properties (Cp, flowrates, etc.)

- Heating medium properties (Cp, flowrates, etc.)

- Worst-case ambient temperature & wind conditions

- Insulation - type & thickness

- Thermal objective - freeze protection thermal maintenance, melt-out, etc.

|

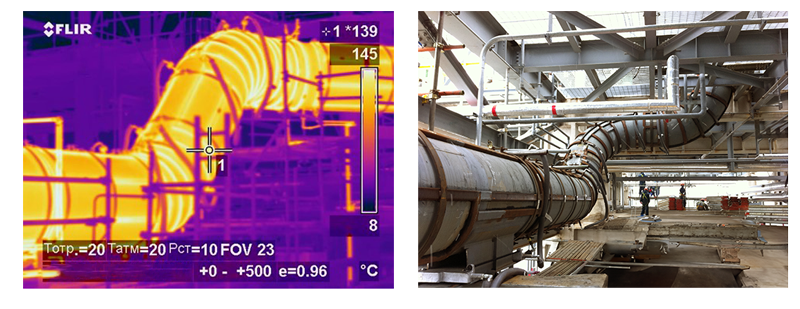

Consistency - Uniformly Distributed Heating System

Unlike tube tracing which depends on variable field installation techniques, ControTrace is an engineered solution that gets it right the first time. Engineered to meet the thermal performance objectives of the process with consideration for start-up, extreme process upset conditions, shut-down maintenance, while operating under all ambient weather conditions. ControTrace is capable and cost effective for all types of applications such as molten sulfur, sulfur vapor, asphalt, crude, urea, acid gases, polymer, plastics and resins for any of your thermal objectives, such as freeze-protection, bulk process thermal maintenance, maintaining uniform pipe wall temperature and high-heat rate requirements like melt-out.

Fig 2: Infrared thermal image showing the uniform coverage of ControTrace paneling on large diameter pipe.

Maximize Process Up Time

- ControTrace external heating systems eliminate potential for product or heating fluid cross-contamination [Fig 3.] which can occur in fully jacketed thermal solutions.

- ControTrace utilizes robust heating elements, SA 178 Grade A boiler tube pressure rated per ASME Section VIII, Div.1, which are 2-3x thicker than typical tracing for extended operational life. For higher pressure or more aggressive environments an optional SA-312 Grade TP316, is available.

- Minimize thermal stresses - uniform distribution of heat (described above) eliminates thermal-stress distortion that occurs when a heated section receives high-heat input while another section is relatively cold.

Fig 3: Illustrations show the contamination risk of a fully jacketed thermal solution where (left) the product can become contaminated with heating fluid or (right) product leaks into heating fluid system.

Cross-contamination of product or heating fluid is a risk for any fully jacketed thermal solution due to possible defects in valve or fitting castings, cracks in base components or core piping, and defective or metallurgically compromising harmful welds. The risk even becomes substantially higher for chemically aggressive processes, such as acrylic acid, cyanuric chloride, dimethyl terephthalate (DMT), phthalic anhydride (PA), sodium, sulfur, phosphorous and various foodstuffs2, making the benefits of an external system like ControHeat highly desirable, to minimize risk to operational costs and to capital equipment.

The costs of cross-contamination of the product are mostly obvious and can be costly. However, contamination of the heating medium can cause skyrocketing operational costs or even worse, corrosion throughout the heating system, including steam generation or hot-oil heating equipment, leading to significant shut-down times and capital equipment replacement costs.

Compared to other solutions, fully jacketed solutions can provide the most heat when necessary. For many or most applications ControTrace can easily meet the technical thermal performance objections for a much lower total costs while not having some of the problems like cross-contamination shown in Fig 3 and described above.

While CSI has provided, and still provides the highest integrity jacketed piping solutions in the industry, it is the above reasons, along with costs effectiveness that we recommend ControTrace except when specific conditions and requirements demand jacketed solutions. Please see our fabricated/jacketed piping page (link) to understand the key details and nuances that make CSI the preferred supplier for that solution.

Increase Operational Efficiency

- Improved conductive heat transfer via ControTrace’s contoured contacting surface.

- Engineered thermal performance, uniform heat distribution & CSI’s thermal guarantee.

- Customizability or formability allows for use in panel configuration around large diameter pipe, or special fits around pipe fittings or tank and vessel, nozzles and vents.

- Optimized circuit lengths, low pressure drops, reduce infrastructure, lowering total system installed and operational costs.

- Higher uptime, lower maintenance, and predictable performance also reduce operation cost.

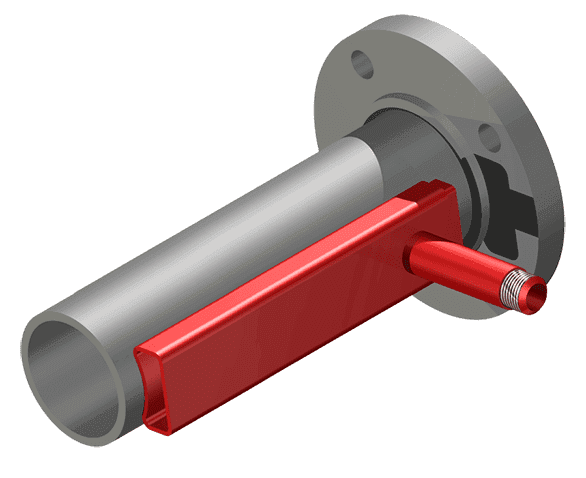

ControTrace - Basic Configurations & Install

The basic ControTrace configuration, shown in Fig 4, is a 2-in. by 1-in. rectangular shaped formed tube, heat tracing element. One of the 2-in. sides is contoured to closely fit the outside diameter of the pipe or vessel onto which it will be placed. As standard practice, a thin layer of heat transfer compound is spread onto the contoured surface of the ControTrace, maximizing conductive contact with the o.d. surface of pipe or vessel in case of imperfections of the latter.

Fig 4: Cut-away profile of a single ControTrace heating element installed (banded) onto 3-in process pipe.

ControTrace® is a “bolt-on” solution, commonly secured to the pipe or vessel with high-strength banding, where no welding is required. The ControTrace elements are engineered and fabricated to specific lengths, Fig 5, considering the heating objective and heating medium requirements (such as steam condensate). The end of the fabricated ControTrace elements are closed (sealed via welding) and the inlet and outlet connections are added to enable heating medium transfer from one to the next, via a flexible jumper hose.

Fig 5: - Individual ControTrace heating elements fabricated to specific lengths with jumper hose connecting the heating medium between individual elements. The ends of the tubing are closed (sealed viawelded), and inlet and outlet connections are added to enable heating medium transfer.

During operation, the heating medium (typically steam or heating fluid) flows through the heating element and transfers its heat through the heat transfer compound and into the pipe/vessel wall and into the process. The number of heating elements required depends upon the design objective and the design conditions. Most ControTrace® applications are designed to maintain a process temperature (to keep liquid flowing) or a minimum pipe/vessel wall temperature (to prevent vapor condensation). CSI utilizes finite-difference computer modeling to simulate and predict temperature profiles and heat transfer rates based upon process, ambient, piping, and insulation conditions.

When multiple elements are required, these are most often joined together in a panel configuration to minimize the number of inlet/outlet connections. Panel configuration can be seen in Fig 2 above and covered in greater detail on the linked web pages below, ControTrace on Tanks and Vessels and ControTrace on Piping.

When process valves and instrumentation such as Coriolis meters need critical heating CSI is the creators of the world-renown bolt-on jacketed heating solution, ControTrace.

ControTrace is used throughout the refining, chemical, petrochemical, shipping and rail industries on pipes from small to large along with tanks, reactors and vessels.

Trusted Thermal Process Solutions Provider

We offer heating evaluations for your existing installation or upcoming projects. In addition to Controtrace we are a provider and experienced for all the thermal heating methods including tube tracing, jacketed-piping, valve-jacketing, and others making us a technology neutral solution provider. Take a moment to talk to the experts at CSI and we will give you a professional, experienced and honest assessment of what we can do, or not do, as your trusted thermal process solution provided.

ControTrace on Tanks and Vessels

|

ControTrace on Piping

|

- Ensuring Uniform Heat Distribution in Sulphur Vapor Lines. David R. Hornbaker, Controls Southeast.

- Maintaining Process Temperature with Bolt on Jackets. Henry P. Gaines, Jr., PE